The APM650™ packaging metrology system from ZYGO is a new inspection tool intended for automated measurement of panel-based PCBs and other advanced packaging applications. It offers 2D and 3D measurements for a range of surface features with sub-micron lateral precision and sub-nanometer vertical precision.

Powerful Performance

Coherence Scanning Interferometry (CSI) is the measurement technology used at the core of the APM650 system.

This non-contact method provides high-precision and high-value surface metrology advantages, including:

- Sub-nanometer measurement precision is independent of field magnification

- Measures almost all types of surfaces, from rough to super smooth, such as thin films, large steps, and steep slopes

- SureScan™ vibration tolerance technology - robust operation in almost any environment

- Gage capable performance - excellent precision and repeatability for the most challenging production applications

- Mx™ software facilitates seamless data exchange with other ZYGO Profilers including ZeGage, Nexview, and NewView 8000

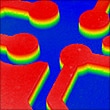

Trace - width, height, space, roughness

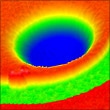

Via Hole - depth, top and bottom diameter, roughness

Via Recess - depth and height

Alignment Mark - offset DX, DY, TP

SRO Pad - depth, top and bottom diameter

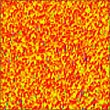

Surface Roughness - Ra for all surfaces

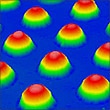

Solder Bump - width, height, coplanarity, spacing

Maximize ROI

The APM650 has a metrology area capable of accommodating lateral dimensions up to 650 x 650 mm, which makes it able of accommodating even the largest of PCB substrate panels currently available. It also ensures that the system provides value for many years.

Customized sample holders and chucks are available in order to adapt the system for smaller panels or even singulated substrates to increase application flexibility. The system’s built-in recipe-driven automation software allows hands-free metrology of a number of features on each panel, all in a single workstation. Also, the software increases process knowledge and reduces production time.